Aerial Lift Safety for Operators: Most Common Accidents and How to Avoid Them

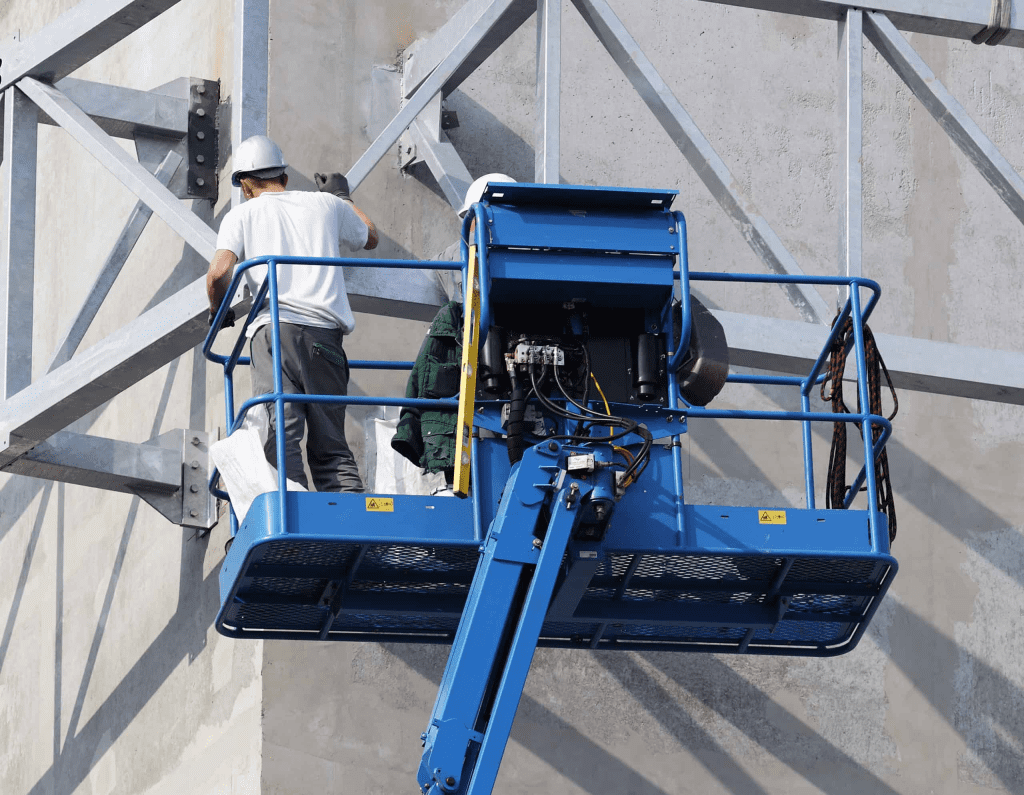

Aerial Lift Operator Safety Guide: Common Accidents and How to Prevent Them

Working on aerial lifts—like boom lifts and scissor lifts—comes with serious risks. Whether you’re 10 feet off the ground or 60, one small mistake can lead to a major injury or even death. Falls, tip-overs, electrocution, and crushed-by incidents happen more often than they should.

The good news is that most aerial lift accidents are 100% preventable with the right training, habits, and jobsite setup.

In this guide, you’ll learn:

- The most common types of aerial lift accidents

- What causes them

- How to avoid them

- What OSHA requires

- What new technology can help keep you safe

Let’s get started.

Common Aerial Lift Accidents and What Causes Them

Here are the most frequent aerial lift accidents you need to watch out for, what causes them, and what can go wrong:

| Accident Type | What Causes It | What Can Happen |

|---|---|---|

| Falls from platform | No fall protection, stepping off lift, guardrails open | Serious injury or death from height |

| Tip-overs | Unstable ground, overreaching, high winds | Operator ejected or crushed by the lift |

| Electrocution | Contact with overhead power lines | Shock, burns, cardiac arrest, fatal injuries |

| Equipment failure | Poor maintenance, hydraulic leaks, tire blowouts | Sudden drops, tip-overs, crush injuries |

| Struck-by incidents | Swinging booms, tight spaces, poor visibility | Head trauma, crushed limbs, serious injury |

Fall Hazards: Why Operators Fall—and How to Stop It

Falls from aerial lifts are the #1 cause of death for lift operators. These happen when:

- You’re not tied off in a boom lift

- You stand on guardrails or climb out of the platform

- The lift jerks or hits something while you’re moving

- Guardrails are missing or unlocked

How to prevent falls:

- Always wear a harness with a lanyard attached to an anchor point when using a boom lift

- Never climb out of a platform unless it’s part of a rescue plan

- Keep both feet on the floor of the platform—don’t use buckets or boxes for extra height

- Double-check guardrails and mid-rails are secure before using the lift

Tip-Overs: What Makes a Lift Fall Over

Aerial lifts are top-heavy and can tip in a second. This usually happens when:

- The lift is on a slope, hole, or soft ground

- The boom is overextended sideways

- Wind gusts hit the platform

- The lift is driven while elevated

Stay upright by:

- Inspecting ground conditions before use

- Using outriggers and wheel chocks on uneven ground

- Checking the wind speed—stop work if winds exceed 28 mph for boom lifts

- Lowering the platform before driving

Electrocution: Hidden Overhead Hazards

Aerial lift platforms often work close to power lines. One wrong move and the lift—or your body—can come into contact with live wires.

Stay safe by:

- Staying at least 10 feet away from power lines (more for high voltage)

- Doing a full site inspection for overhead hazards before raising the lift

- Using spotters to help guide you around wires

- Never working in electrical storm conditions

Other Hazards That Catch Operators Off Guard

Some risks aren’t as obvious, but they’re just as dangerous:

- Crushing between the lift and overhead beams

- Struck-by injuries from swing-arms or lift movement in tight spaces

- Platform collapse from worn or damaged components

- Slips and trips inside the platform from tools or clutter

Stay alert by:

- Keeping platforms clean and tools tied down

- Inspecting all lift components before every shift

- Avoiding overhead obstacles—watch up and around

- Using barricades or tape to keep people out of your work zone

What OSHA Requires for Aerial Lift Training

If you’re operating an aerial lift, OSHA says you must be trained under 29 CFR 1926.453 (for construction) or 1910.67 (for general industry).

Your training must include:

- How to operate the specific type of lift (scissor, boom, etc.)

- Hazard recognition (like tip-overs, falls, and power lines)

- Safe driving and raising techniques

- Emergency procedures

You’ll also need:

- Hands-on practice using the lift

- A written or verbal test to show you know the material

- Retraining if you change equipment, have an accident, or are seen operating unsafely

How Jobsite Design Impacts Aerial Lift Safety

Where and how you use a lift affects your safety every minute you’re in the air.

Smart layout planning includes:

- Flat, solid ground with no potholes or slopes

- Barricades or cones to separate workers from your lift zone

- Proper storage of materials so you don’t need to overreach

- No overhead pipes, beams, or ductwork that could pin you

Managers should review the layout every time something changes—like moving racks or storing new materials.

New Safety Tech for Aerial Lifts

Technology is helping prevent more accidents with features like:

- Tilt sensors that sound alarms if the lift gets unstable

- Load sensors that warn if you’re carrying too much weight

- Platform control lockouts to stop the lift if conditions are unsafe

- Fall restraint systems that stop a fall before it starts

- Wireless kill switches that let ground crews shut down the lift

These tools support your training—but they don’t replace it. You still need to stay sharp every shift.

Real-World Stats: Why This All Matters

According to OSHA and industry data:

- Over 26 workers die each year from aerial lift accidents in the U.S.

- Most deaths are caused by falls, tip-overs, and electrocution

- Boom lifts are more dangerous than scissor lifts—because of height and swing radius

- In nearly 70% of these cases, the accident could have been prevented

Frequently Asked Questions (FAQ) for Aerial Lift Operators

1. When do I need to wear a harness in an aerial lift?

You must wear a full-body harness with a lanyard when operating a boom lift. It needs to be tied off to an approved anchor point in the platform. For scissor lifts, a harness is not required by OSHA, but guardrails must be secure at all times.

2. Can I drive the lift while it’s elevated?

Only if the lift is rated for elevated travel—check the operator’s manual. Even then, you should drive slow and carefully. Never move a lift on a slope or uneven surface while raised.

3. What’s the biggest cause of tip-overs in aerial lifts?

Tip-overs usually happen because of:

- Working on uneven or soft ground

- Overreaching or leaning too far from the basket

- Strong winds hitting the platform

- Driving the lift while extended

Always inspect the ground, stay inside the rails, and don’t work in wind speeds above 28 mph for boom lifts.

4. How far do I need to stay from power lines?

Stay at least 10 feet away from power lines carrying up to 50kV. For higher voltage, the distance must increase. Always check voltage with your supervisor or site manager. Never trust a line is safe just because it looks insulated.

5. What should I inspect before using an aerial lift?

Do a full pre-use inspection, including:

- Tires, outriggers, and ground surface

- Guardrails and gates

- Hydraulic leaks or hose damage

- Control functions and emergency stop

- Harness and lanyard (for boom lifts)

Report problems before using the lift. Don’t take chances.

6. How often do I need aerial lift training?

You need certified training before you ever operate an aerial lift, and retraining if:

- You switch to a new type of lift

- You’re involved in an accident or near-miss

- You’re observed using the lift unsafely

Training must cover hazards, safe operation, and emergency procedures.

7. Can I exit the platform while the lift is in the air?

No, not unless your lift is designed for that and you have a fall protection and rescue plan in place. Most lifts do not allow exit at height. Climbing out without a plan is a serious fall risk—and a violation of OSHA standards.

8. What should I do if the lift gets stuck or starts to tip?

Stay calm and:

- Use the emergency stop or lower controls

- Call for help—use your radio or phone

- Never jump out of a tipping lift

- If stuck, wait for someone trained in ground controls to lower the platform

9. What do the alarms and lights on my lift mean?

Most lifts have tilt sensors, overload alarms, and proximity alerts. If you hear a beep or see a flashing light:

- Stop moving immediately

- Check the alarm type in your manual

- Fix the issue or call a supervisor before continuing

These alarms are early warnings—don’t ignore them.

10. What’s the best way to prevent aerial lift accidents?

Stick to the basics every time:

- Do a full pre-use inspection

- Stay inside the guardrails

- Use a harness in boom lifts

- Keep a safe distance from power lines

- Stay alert to your surroundings

Don’t rush. Don’t assume. Always double-check.