Aerial lifts are commonly used during construction projects, and they allow workers to safely perform many jobs above the ground. Yet, aerial lifts are also a leading cause of construction accidents in the United States, according to The Center for Construction Research and Training. This is why all job sites need an aerial lift safety checklist.

OSHA reports that an average of 25 Americans die from aerial lift and scissor lift accidents each year. Our training helps workers avoid such accidents and injuries on the job. That’s why stakeholders must prioritize their organization’s aerial lift training checklist – a little education can go a long way in preventing accidents.

What Is an Aerial Lift Safety Checklist?

The Occupational Safety and Health Administration offers safety guidelines to help employees avoid many of the most common on-the-job hazards. Fail to follow these guidelines and the odds of an accident occurring goes up significantly.

Worker safety must always come first. An aerial lift safety checklist can help workers keep safety a priority day after day. With a checklist in their arsenal, workers are empowered to complete duties in the safest way possible. A thorough inspection of equipment can help workers better understand the condition of their tools and ensure lifts are used properly.

Of course, even the most detailed of safety checklists can’t make up for a lack of worker training. Without the proper certification, employees are bound to find themselves involved in a workplace accident. Aerial lift training courses can teach workers how to stay safe and use the equipment effectively. Since OSHA requires training of all aerial lift operators, it’s important to prioritize education. Without proper training in place, your workers may find themselves at an increased risk of accidents and injuries. Even if they manage to sidestep workplace accidents, OSHA has been known to levy expensive penalties against companies that don’t properly train their workers.

Start with Aerial Lift Safety Training

Before developing an aerial lift safety checklist, you’ll want to ensure that all employees are adequately trained and certified. A checklist is nothing without context – if your workers don’t understand industry safety policies, they may gloss over the most important aspects of your list. Training can teach employees how to safely operate a wide range of scissor lifts. They’ll learn how to perform pre-job inspections, how to recognize and remove job site hazards, and how to navigate around colleagues and equipment when operating a lift indoors.

Aerial lift safety training can also ensure that employees know how to operate scissor lifts over various types of terrain. Workers will learn how to safely use all lift controls and how to abide by safety guidelines to prevent accidents. While scissor lift inspection checklists are undeniably useful, workers must have a baseline of knowledge to know how to use this equipment safely. Fail to train workers and your business may see an uptick in the number of workplace accidents or even be subjected to expensive OSHA fines.

What to Include on Your Aerial Lift Checklist

An aerial lift checklist can help you comply with OSHA safety standards and prevent accidents. Most important, this checklist helps you and your coworkers stay safe on the job.

Now, let’s look at what is included on a aerial lift safety checklist:

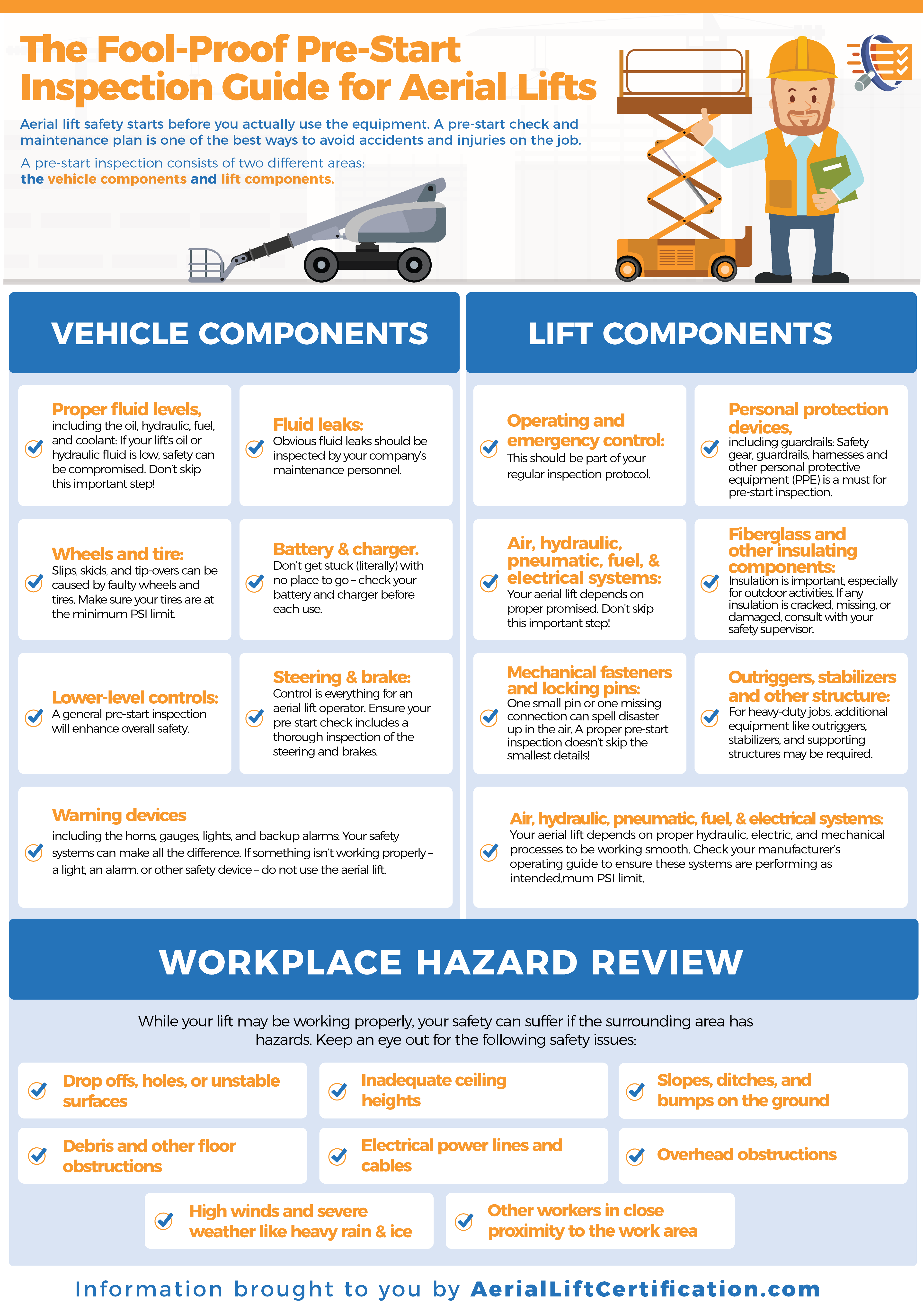

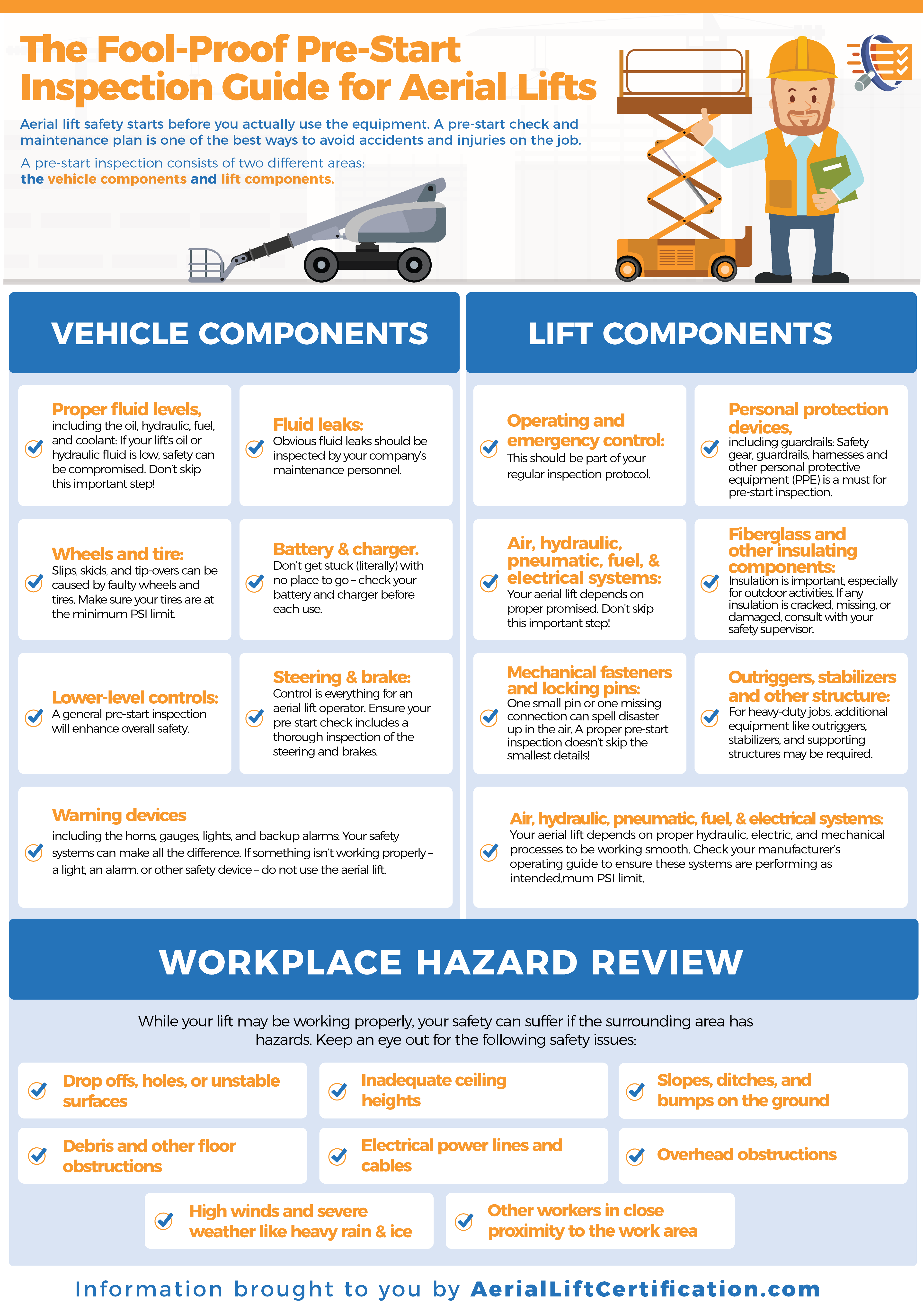

Click image to enlarge

Share this Image On Your Site

1. Aerial Boom Lift Pre-Use Inspection Checklist

Every aerial lift job should start with an inspection of the lift, as this helps prevent damaged or faulty parts from creating hazards. The inspection should cover the vehicle and the lift, including:

- All fluid levels, including the oil, fuel, and coolant

- Any fluid leaks

- Wheels and tires

- Battery and charger

- Lower-level controls

- Horns, gauges, lights, backup alarms, and other warning devices

- Steering and brakes

In addition, parts of the lift to inspect include:

- Operating and emergency controls

- Personal protective equipment

- Air, hydraulic, fuel, and electric systems

- Fiberglass and other insulating components

- Missing or hard-to-read charts, warnings, or instructional markings

- Mechanical fasteners and locking pins

- Outriggers, stabilizers, and similar structures

- Loose or missing parts

- Guardrail systems

Remember, even a minor defect can cause significant problems that lead to an accident. If an aerial lift inspection checklist turns up damaged or missing parts, work should not begin until they are repaired or replaced.

2. Job Site Factors

Every job site has safety hazards, which is why every aerial lift safety checklist should include a thorough inspection of a work area.

All hazards must be recognized and removed before work can begin. These include:

- Drop-offs, holes, or unstable surfaces

- Low ceiling heights

- Slopes, ditches, and bumps on the ground

- Debris and other floor obstructions

- Live power lines and cables

- Overhead obstructions

- High winds and severe weather like heavy rain and ice

- Other workers close to the work area

The aforementioned hazards can make it difficult to maintain a safe job site, and you need to address them before they get out of hand. Of course, if you enroll in a boom lift safety training program, you can gain the insights you need to remove job site hazards without delay.

3. Fall Protection

OSHA requires aerial lift workers to have proper fall protection equipment. Workers should also have proper training, so they know how to use their safety gear.

Fall protection gear is designed to prevent falls by restricting worker movement. Some types can also arrest falls when they occur.

Before starting a job, use an aerial lift safety checklist for fall protection gear that ensures:

- All workers have the proper gear.

- Workers have body harnesses or restraining belts and lanyards.

- These are attached to a point on the boom or bucket.

- These are not belted off to nearby structures or poles.

- All access gates are closed.

- Workers stand firmly on a bucket floor or platform.

- Workers don’t climb or lean on or over the guardrails.

- There are no planks, ladders, or other devices in the working position.

An aerial lift safety checklist that accounts for fall protection gear is crucial. With this checklist in hand, you’ll be well-equipped to prevent boom lift falls now and in the future.

4. Overhead Protection

Any overhead obstruction can increase the risks of an accident occurring. Forceful impacts, electric shocks, and crushing injuries are all possible. Hitting an obstruction with a platform or sloping on unstable ground can also lead to accidents like tip-overs. Thankfully, there are a number of things you can do on your job site to improve aerial lift overhead protection, including:

- Assume all power lines are live.

- Stay at least 10 feet away from all power lines and cables.

- De-energize live power lines in a work zone.

- Keep an eye out for overhead objects.

- Don’t set up the aerial lift between overhead obstructions.

- Set outriggers on pads or a level surface, then set the

- Use wheel chocks on sloped surfaces.

- Set up work zone warnings like cones and signs.

Overhead protection sometimes goes unaddressed, but you need to account for it. By doing so, you can limit the risks of accidents caused by overhead obstructions.

Safe Operational Practices

Thorough safety training can do wonders to prevent aerial lift accidents. While an aerial lift checklist can help workers stay alert to potential issues, it represents the beginning – not the end – of safe operational practices. Once the lift is in use, operate on the assumption that all electrical wires are live. Stay at least 10 feet away at all times. De-energize power lines in the area to prevent electrocution. This tip can seriously save lives!

It’s also important to be mindful of overhead clearances and objects. Buildings, trees, and power lines must all be accounted for when using aerial lifts. Whenever possible, avoid using lifts between such obstructions. Use outrigger pads to work on a level surface. They can really come in handy when you’re trying to avoid shifting or swaying while you work. When working on a hill, be sure to use wheel chocks, too.

What Not to Do When Operating Aerial Lifts

An aerial lift checklist can indeed go a long way to keep workers safe. Still, it’s equally as important to know what not to do when operating aerial lifts. For instance, it’s incredibly important not to overload the lift with workers or tools. Each model has its own unique load capacity. Fail to respect those limits and an accident may become inevitable.

It’s also important that workers avoid using the lift as a crane. Never carry objects larger than the platform area. Avoid driving with the platform raised, too. Respecting the vertical and horizontal limitations is crucial – aerial lifts are designed to operate within a set of parameters. Push those limits and you could find yourself in over your head.

Put Your Aerial Lift Safety Knowledge to the Test

Think you’re an OSHA aerial lift safety expert? Take our quiz to find out how well you know the ins and outs of safe operation and maintenance of aerial lifts. Of course, if you fall short of your expectations on our quiz, there is no need to stress. Because, if you take advantage of our certification programs, you can get up to speed on all aspects of aerial lift safety.

Get a Jumpstart on Your Aerial Lift Training Checklist

Not sure where to start when designing your ideal aerial lift inspection checklist? There’s no need to worry! By signing up for aerial lift safety training with AerialLiftCertification.com, you’ll learn everything you need to know about preventing accidents on the job.

Convenient online courses allow workers to learn from anywhere with an internet connection. It’s never been easier to learn new skills and develop increased safety awareness. If you’ve been developing your organization’s aerial lift training checklist, ALC offers the very best resources for meeting those goals. Compliant with OSHA guidelines, our courses take about an hour to complete. They protect your most important asset: your employees. To learn more or sign up, contact us online or give us a call at (888) 278-8896.